The Model Jet Engine

True turbine rc model jet engines add the ultimate touch of realism to a radio controlled jet, and commercially produced units for rc use are widely available - if not always affordable!

Turbine rc jet flying, however, is not for the novice. In fact, this demanding sector of radio control flying is seen by many as the pinnacle of the pastime!

Endless hours of flying experience and an impressive budget are needed to actively participate in flying proper radio control jets powered by real gas turbines. Even the smaller model jet engines are not cheap - and that's on top of the cost of the jet itself, the radio gear and all the other necessary accessories.

So jet flying is serious business indeed that can easily run in to thousands of bucks, but ultimately has to be one of the most rewarding of all rc flying disciplines.

Shown right is a JetCat model turbine, one of the first and more popular commercially produced model jet engines readily available. Wren, from the UK, is another favourite model jet engine manufacturer with an excellent reputation although sadly the company was liquidated.

Shown right is a JetCat model turbine, one of the first and more popular commercially produced model jet engines readily available. Wren, from the UK, is another favourite model jet engine manufacturer with an excellent reputation although sadly the company was liquidated.

Here's a video of a JetCat P80 being bench run:

Pre-turbine Power Options

Before model jet engines appeared on the scene, rc jets always lacked the authenticity of having a true gas turbine. Previously radio control jets had to be powered by either an engine with a propeller (thus spoiling the look of the aircraft) or ducted fan units.

A ducted fan unit (shown right), is mounted inside the jet's fuselage. This at least means there is no propeller to ruin the look of the jet, but early (pre-electric power) glow plug powered ducted fans were very noisy, giving a very unrealistic high pitch whining sound.

A ducted fan unit (shown right), is mounted inside the jet's fuselage. This at least means there is no propeller to ruin the look of the jet, but early (pre-electric power) glow plug powered ducted fans were very noisy, giving a very unrealistic high pitch whining sound.

Nowadays electric powered fan units are commonplace and while the noise isn't particularly realistic, it is better than an IC fan unit.

More recently, EDF impellers have increased from the typical 5 or 6 blades to 11 or 12. This results in more air movement through the fan being heard, rather than motor noise, in turn resulting in a more convincing sound.

EDFs have made flying a model rc jet much more accessible within the hobby.

Pulse jets were/are another option but these more resemble rocket motors rather than jet engines. Pulse jet motors are long slender motors that, because of their size and shape, typically need to be fixed to the outside of the fuselage.

A pulse jet runs at full throttle for a short time, the fuel (usually gasoline) being pulsed through inlet valves. An even more unrealistic sound than an EDF, a pulse jet motor kind of sounds like an impressively drawn-out fart! ![]() .

.

Once the fuel is spent, the motor cuts and the pilot glides the jet back to land. Fun maybe, but not particularly realistic!

Above: an RC pulse jet motor.

Model Jet Engine Operation

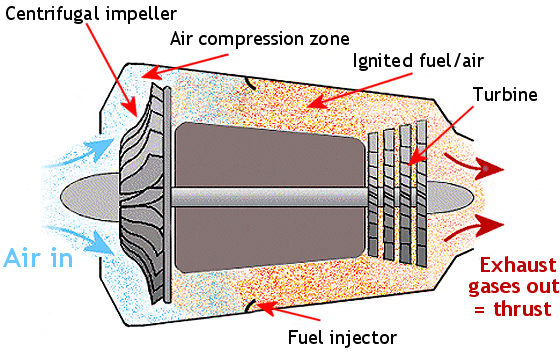

The most common type of model gas turbine is the centrifugal flow turbine as opposed to the lengthier axial flow turbine.

The big difference between centrifugal and axial flow turbines is in the stage of air compression.

In a centrifugal flow unit, air is sucked into the front intake by the spinning impeller and immediately flows over the compressor (stator).

The stator greatly compresses the incoming air before it passes into the combustion chamber. This intense compression increases the pressure and hence temperature of the air, making it more effective when it mixes with the fuel.

Alternatively a centrifugal impeller is used whereby this single component does the job of intake impeller and compressor stator, by drawing in the air and throwing it outwards at great force to compress it against the inside of the can.

The kerosene based fuel, commonly called Jet A1, is introduced into the combustion chamber as a very fine mist and so mixes easily with the now highly compressed air. This fuel/air mixture is then ignited by a small glow plug.

As the fuel/air mixture ignites and explodes within the chamber, the coned shape of the chamber and the incoming flow of new air forces the mixture rearwards towards the turbine. The rapid outward flow of the gases spins the rear turbine which in turn spins the impeller at the front of the jet engine (both components are connected by a central shaft), and so continuing the process.

The gases (exhaust) finally get squeezed through the narrowing jet pipe at the very rear of the engine, exiting at great speed and pressure thus generating the high levels of thrust associated with jet turbines.

The simplified drawing below shows the basic principle of a centrifugal flow model jet engine:

Below is a cool video of what goes on inside a model jet engine...

Engine Start-Up

Model jet engines need to be initially spun up without burning any fuel, as full size ones do. Only when the turbine has reached the necessary revolutions per minute (RPM) can the fuel be introduced into the chamber and the engine can begin to operate normally.

This initial part of the start-up sequence can be done by blowing compressed air into the front of the engine to spin the compressor, or an external high-RPM electric starter can be used, similar to those used for starting rc airplane engines.

A third and increasingly common option is an integrated small electric starter motor. This of course gives you the auto-start option, which is true to a real gas turbine.

Below is another video of model jet engines in action, this time in a superb radio controlled F-14 Tomcat:

Model Jet Engine Reading

The actual technicalities of model jet engines for radio control use are obviously more complex than this page outlines, but aside from the wealth of information available on the internet there are some good books on the subject, worth considering:

Gas Turbine Engines for Model Aircraft (shown right) by Kurt Schreckling and Keith Thomas.

"I found the book easy to follow and I've found that Kurt Schreckling and Keith Thomas have made an excellent job of bringing the complexities of the gas turbine to a level the average person can understand and learn from..." (Amazon customer review).

Model Jet Engines

(shown right) by Thomas Kamps and Keith Thomas.

"Until I saw this book I didn't believe it would be possible for an amateur to build a jet engine, capable of running at 100,000 rpm . Kamps book explains clearly how, with a reasonably well equipped workshop, a model engineer can build an efficient working jet engine..." (Amazon customer review).

The very first time I saw a true rc turbine jet in action was at my local flying club field, in the early 1990s. A member of staff from a local hobby shop brought it along to our patch to demonstrate, and I was awestruck!

Sadly I've never reached the dizzy heights of radio control jet flying, but maybe one day I might achieve it. For now I'll have to settle for my EDF flying!