Model Airplane Kits

- is Building Right for You?

Sales of traditional balsa model airplane kits took quite a hit with the advent of RTF and ARF planes, but in recent years they seem to be bouncing back.

The Ready To Fly and Almost Ready To Fly planes have been blamed for the decline in traditional aeromodelling, but the comeback that balsa kits are now seeing can perhaps be put down to those RTF and ARF owners now being involved in the hobby long enough to want to build their own plane, rather than buy just another stock mass-produced one.

What's In a Model Plane Kit?

A trad model airplane kit typically comprises a plan and building instructions, the balsa and ply wood needed to construct the plane and most, if not all, of the hardware such as servo linkages, control horns, undercarriage parts, motor mount, fuel tank etc.

Essentially, the kit contains all you need to complete the airframe, leaving you to buy the covering material, radio gear and engine/motor and associated accessories. Some kits do include a covering material (typically an iron-on plastic film) but this isn't usually the case.

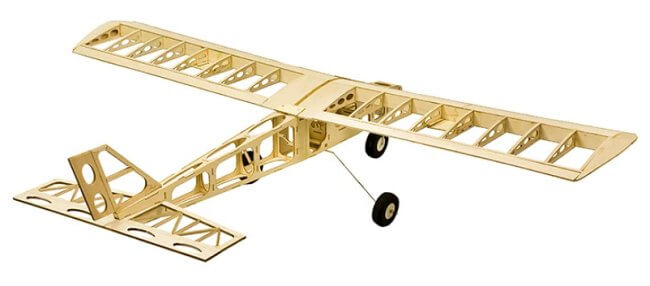

Above: a typical model airplane kit will contain all you need

to build the complete airframe.

The components of the plane such as wing ribs and fuselage formers may already be cut out either by CNC machine or, more commonly these days, laser. If the parts are not pre-cut then the outline of each one will be printed on to sheet wood and it's your task to accurately cut them out with a sharp modelling knife. Certainly CNC/laser-cut kits are the nicer option!

Strip balsa will also be included in the kit for use as wing spars, leading and trailing edges, fuselage longerons etc.

Incidentally, despite its often soft feel, balsa is actually a hardwood. It is ideally suited to model plane kit construction because of its excellent strength to weight ratio.

In 2020 there was a worrying global shortage of balsa to the modelling industry, largely due to one of the major balsa mills being sold and an increase in demand for balsa to be used in wind turbine blades.

Fortunately this seems to have settled down a bit now, and balsa stocks are returning to our model shops.

As well as balsa wood, thin model-grade plywood is also commonly used in certain areas of model airplane construction, where more strength is required such as engine bulkheads (firewalls) and landing gear plates.

Model Airplane Construction

The building of a model plane kit is usually done over the plan which must be laid out on a flat modelling board.

I say "usually" because there are kits around these days that don't include a plan. These are kits of laser cut parts that tightly interlock and you stick together with thin cyanoacrylate (CA) glue. Because the glue sets instantly, the parts don't need to be pinned down over a plan.

This Cloud Dancer rc trainer plane is one such example...

Above: a laser-cut balsa and ply kit, the Cloud Dancer trainer.

Typically, however, the balsa parts are glued together with some form of wood glue or specialist modelling glue. White PVA and Aliphatic glues are typical examples. In areas where greater strength is needed, 2-part epoxy is commonly used.

The parts are held in place over the plan with pins until the glue sets, so your modelling board needs to be soft enough that a pin can be pushed into it. Sheets of two or three inch thick insulating foam used in the construction industry make ideal modelling boards, as do boards made from end-grain balsa blocks laminated together.

An alternative is to have a flat steel sheet and use powerful Rare Earth magnets to hold the parts in place, instead of pins.

Whatever is used for the board, the key issue is that it needs to be perfectly flat. Any humps or twists in the board get transferred to the plane during construction, and that's not good.

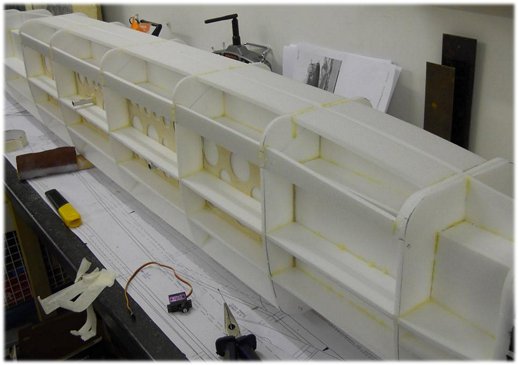

Above: A CAP 21 fuselage takes shape over the plan.

Once all parts of the plane have been built then the wood needs to be carefully sanded to a smooth finish, particularly the joints. Any unwanted holes and other imperfections can be filled with lightweight filler and then sanded to shape.

Once all parts of the plane have been built then the wood needs to be carefully sanded to a smooth finish, particularly the joints. Any unwanted holes and other imperfections can be filled with lightweight filler and then sanded to shape.

For many, including myself, sanding is the worst job of all but it's worth taking the time because any lumps and bumps in the airframe will show through the covering and potentially spoil the look of the finished plane. So despite being a nasty task, it's worth taking your time with the sanding and getting a nice finish. Use fine-grade sand papers such as 400, 600 and 800 grit for example.

Important health tip - always wear some kind of protective mask when sanding; balsa dust is very fine and easily inhaled, which isn't particularly good for you!

Getting it Covered

When the construction and final sanding of the airplane parts is complete, they are then covered in some kind of covering film, a common choice being a heat sensitive film which is applied using an iron.

The heat melts the adhesive backing which sticks the film to the balsa, then the iron or a heat gun is used to shrink the film over the plane parts.

There's a definite skill to using such coverings and the manufacturer instructions regarding iron temperature settings should be followed carefully; if in doubt, practice on some spare balsa first.

The following video will introduce you to such covering methods if you're new to them. This rc airplane covering video is the first of a series, you can find the rest on YouTube.

Heat-shrink covering is about the most commonly used covering on radio control planes. More traditional alternatives are lightweight tissue paper (or even silk) applied with a liquid called 'dope'. The dope is applied to the airframe to stick the covering down, and then to the entire covered surface. As the dope dries it shrinks, tightening the tissue as it does so.

Heat-shrink covering is about the most commonly used covering on radio control planes. More traditional alternatives are lightweight tissue paper (or even silk) applied with a liquid called 'dope'. The dope is applied to the airframe to stick the covering down, and then to the entire covered surface. As the dope dries it shrinks, tightening the tissue as it does so.

Many builders of small scale model airplanes, such as rubber-powered ones, still use this method but these days ultra lightweight iron-on coverings are available to replace the tissue and dope method, should you prefer.

Balsa/ply ARF RC Airplane 'Kits'

If you want a gentle introduction to traditional model airplane building techniques then an ARF (or ARTF) - Almost Ready To Fly - kit might be the answer.

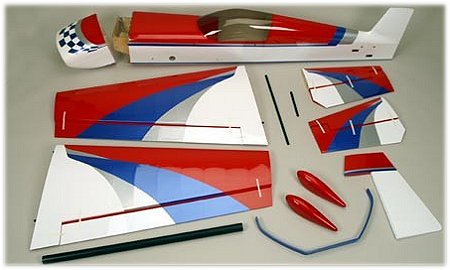

ARFs are 90% finished, including the covering, and they are mostly of balsa and ply construction. All you need to do is some final assembly work (fitting hardware) and install the engine/motor and radio gear yourself. The photo below shows a typical ARF kit, fresh out the box:

ARF airplane kits have become very popular in recent years and there are some excellent quality kits out there - and some very bad ones too!

The majority of such kits (good and bad) come from the Far East; if you're going to buy an ARF then do some thorough research before you buy. Internet forums such as RC Groups, RC Universe and Model Flying (UK) are invaluable places for finding out about a certain kit.

The influx of high quality ARF rc airplanes in to the hobby has been largely blamed for the demise in traditional kit building by aeromodellers, but ARF planes are an excellent solution for those modellers who want to fly a traditionally built balsa/ply plane but just don't have the time or inclination to build one themselves.

Read more about ARF rc airplanes.

Foam RTF RC Planes

Although there is a very wide selection of traditional balsa model airplane kits available, and an even wider selection of ARF ones, nowadays however it's quite normal for model rc planes to be constructed from foam. Most electric powered RTF rc airplanes are made this way and in the last few years there has been a huge surge in the number and variety of foam planes available.

Above: RC airplanes of foam construction are commonplace,

particularly in the beginners sector.

Foam rc planes are very convenient and are cheaper to buy than balsa ones, simply because manufacturing costs are lower. The type of foam typically used in model airplane construction is very durable and so the plane can withstand bumps and knocks greater than a balsa/ply airplane can. For these reasons foam rc airplanes are very popular as beginner rc airplanes.

The downside to 'foamies' is that because foam is a relatively soft material, it's easily damaged by careless handling. The so-called hanger rash is a common issue with foam planes!

Balsa vs. Depron

Although balsa wood has long been the main material used in model airplane kit construction, there is a growing number of aeromodellers who are using Depron foam.

Although balsa wood has long been the main material used in model airplane kit construction, there is a growing number of aeromodellers who are using Depron foam.

Originally manufactured for floor insulation in the construction industry, the qualities of Depron were soon noticed by aeromodellers who quickly discovered its suitability for model plane construction.

The rigidity and ultra light weight of this foam sheet make it an ideal substitute for balsa and some incredible planes have been made with it. The pic below (img© from the Model Flying forum) shows the fuselage of a 134" span Lancaster being constructed from Depron...

It's amazing to see that such a thin foam can be used to construct such a large-scale rc plane. Of course, balsa and/or ply reinforcements are necessary in places but it just goes to show what can be done with Depron.

RC Airplane Construction Accessories

Various modelling tools and accessories are needed to construct a model airplane from a kit, a typical list would include....

- Modelling knives & blades.

- Razor saw.

- Sanding block and paper.

- Modelling pins.

- Steel rule(s).

- Engineer's square(s).

- Various adhesives.

- Modeller's vice and pliers.

- Small metal files.

- Small screwdrivers.

As mentioned earlier a modelling board is also essential, this needs to be something rigid and completely flat so that the plane will be straight and true.

You can also buy what's known as a modelling jig, on which to build your plane. Personally I've never used one, although I do have one at the back of the cupboard!

Your local hobby shop, or stores online, will carry all the tools and accessories you need to build a plane from a kit.

Building a model rc airplane from a kit is a truly rewarding thing to do. I can personally recommend doing it, the feeling of self-satisfaction at the end of the job is enormous.

But it's not something that can be rushed. It's a very involved process that will take you time.

If you're looking for a project to undertake during the long winter months (traditionally that's when aeromodellers build their planes), then consider building your next model plane instead of rushing out and buying one that's already made. You won't regret it!